Discover How a Membrane Switch Boosts Resilience and Performance in Instruments

Exploring the Advantages of Membrane Layer Switches in Modern Electronic Tools

The combination of membrane changes into modern electronic devices offers a number of compelling advantages that merit factor to consider. The cost-effectiveness of membrane layer changes positions them as a feasible choice for manufacturers seeking to maximize their product offerings.

Design Adaptability

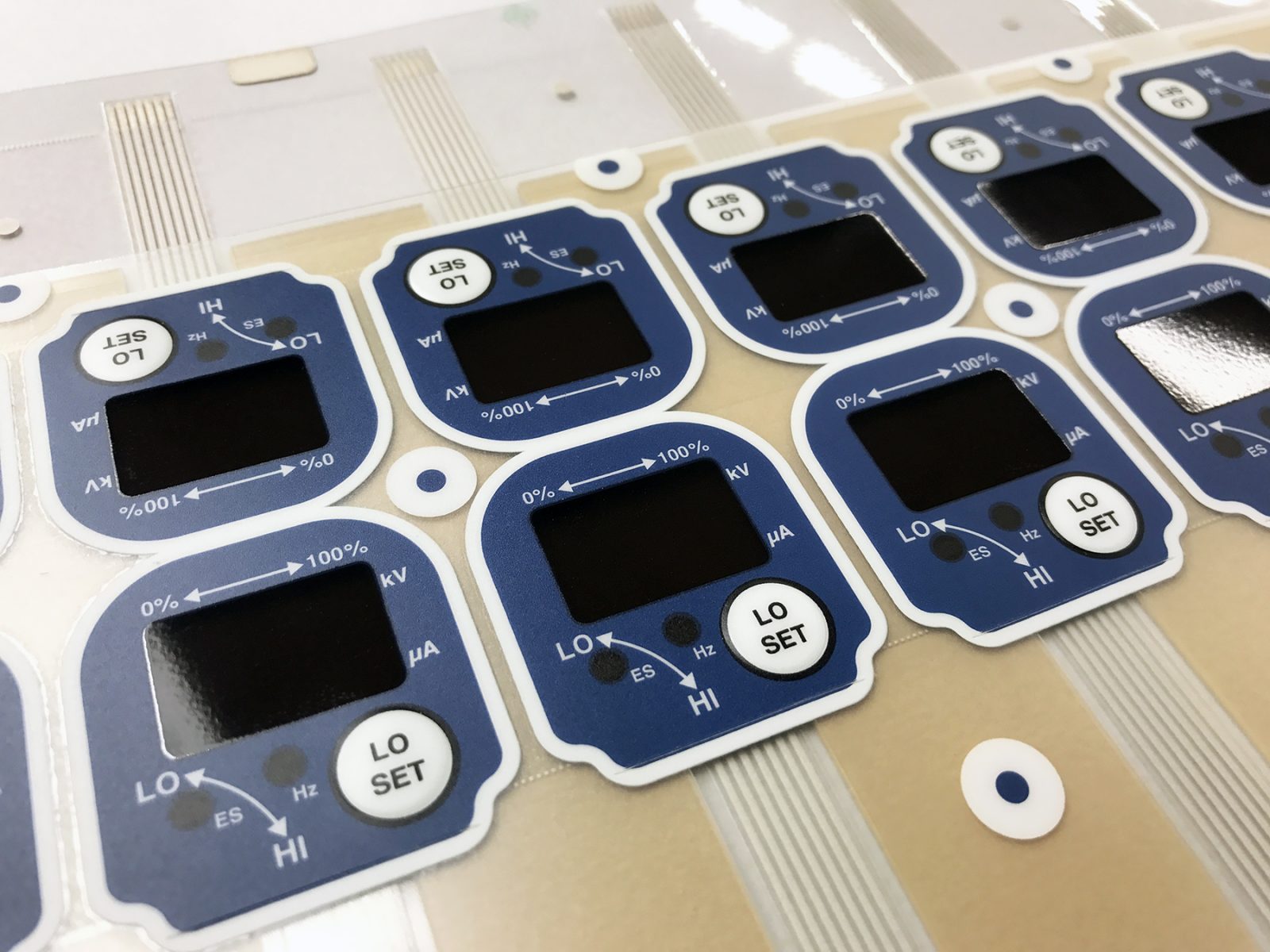

Design adaptability is an essential benefit of membrane layer buttons, allowing producers to develop customized user interfaces that meet particular functional requirements. This flexibility is crucial in an age where user experience and performance are extremely important. Membrane buttons can be developed in numerous shapes, sizes, and shades, enabling aesthetic assimilation right into varied electronic devices.

The printed graphics can be customized to match branding, while the tactile comments can be gotten used to enhance customer communication. Additionally, membrane layer buttons can integrate several layers, enabling attributes such as backlighting and protective overlays, which add to both aesthetic appeal and functionality.

Manufacturers can likewise utilize different products, such as polyester or polycarbonate, to line up with particular application requirements. This flexibility expands to the setup of the button design, allowing the assimilation of several features within a solitary user interface.

The ability to personalize not only improves the usability of electronic devices but additionally enables the incorporation of advanced technologies, such as capacitive touch. Therefore, membrane buttons are an ideal choice for a wide array of applications, ranging from medical equipment to customer electronics, making certain that customer demands are continually fulfilled.

Durability and Durability

Resilience and durability are crucial factors that enhance the charm of membrane layer switches in modern-day digital devices. These buttons are developed to withstand difficult environments, consisting of exposure to moisture, dust, and numerous chemicals. The robust products utilized in their building, such as polyester and polycarbonate, contribute significantly to their resistance versus abrasion and effect, making sure that they keep capability even under laborious problems.

Additionally, membrane layer buttons are inherently secured, protecting against impurities from penetrating the interior elements. This closed building and construction not just lengthens the life expectancy of the switches but likewise reduces the regularity of upkeep and substitutes, which is an essential facet for manufacturers and end-users alike.

One more benefit is their capability to endure considerable cycles of procedure without deterioration in efficiency (Membrane Switch). This characteristic makes them particularly appropriate for applications needing regular use, such as medical gadgets, commercial machinery, and customer electronic devices

Cost-Effectiveness

In addition, membrane layer switches are commonly generated utilizing cost-effective products and procedures. Their lightweight style not just decreases delivery expenses yet additionally allows for less complicated assimilation right into digital devices. This can cause more savings in making prices, as streamlined assembly procedures minimize labor and time demands.

Furthermore, the inherent simplicity of membrane layer switch layouts frequently means fewer elements are needed compared to standard mechanical switches. This decrease partly not only decreases manufacturing expenses but also lessens factors of failing, boosting integrity and efficiency.

In fields where spending plan restrictions are vital, such as customer electronics and commercial applications, the cost-effectiveness of membrane layer changes ends up being particularly useful. Their ability to supply regular performance at a reduced top article lifecycle expense positions them as a sensible option for modern electronic devices. Overall, investing in membrane switches can bring about significant lasting cost savings for organizations and customers.

Personalization Options

Modification options for membrane layer switches are extensive, allowing producers to tailor these components to satisfy particular application requirements. Among the key advantages of membrane buttons is their flexibility in design. Suppliers can select from a series of materials, including polyester, polycarbonate, and acrylic, each offering distinctive benefits in regards to toughness and aesthetic appeals.

Furthermore, membrane switches can be customized in different sizes and shapes to fit unique tool configurations. This versatility prolongs to the consolidation of different shades, graphics, and textures, enabling brand names to keep their visual identity while enhancing user experience (Membrane Switch). In addition, makers can integrate responsive comments attributes, such as printed keys or varying actuation pressures, to improve functionality

The printing modern technology used for graphics and tales can also be tailored, guaranteeing high-resolution pictures and durable prints resistant to use and tear. Additionally, backlighting alternatives, such as LEDs, can be included to boost presence in low-light atmospheres. Personalized circuit styles permit for details capabilities, allowing producers to produce switches that provide specifically to their item's requirements. In general, these considerable customization alternatives make membrane layer switches an engaging choice for modern digital devices.

Applications in Different Industries

Membrane layer switches discover considerable applications throughout a range of markets, showing their flexibility and functionality in countless setups (Membrane Switch). In the medical care industry, they are commonly used in medical devices, such as individual displays and analysis devices, where reliability and convenience of cleaning are vital. Their sealed layout helps avoid contamination, making them ideal for settings that require rigorous hygiene criteria

In the automotive market, membrane buttons play an important duty in control panels and dashboards, providing an instinctive user interface for chauffeurs. The responsive feedback and adjustable attributes improve individual experience while guaranteeing sturdiness versus vibrations and environmental factors.

Moreover, in commercial applications, membrane buttons are utilized in equipment control systems, permitting direct and effective individual interaction. With their convenience, membrane buttons provide a durable solution that meets the varied needs of explanation today's technology-driven markets, view publisher site proving crucial for both performance and visual appeal.

Verdict

In verdict, membrane layer changes offer significant benefits in modern digital equipment due to their design flexibility, resilience, and cost-effectiveness. The lightweight nature of membrane changes more adds to lowered delivery expenses and simplicity of combination.